Craftsmanship

Our corporate philosophy is rooted in a constant pursuit of growth, never settling for the status quo.

This spirit is symbolized by our founder’s motto—"Self-reliance, Professionalism, No.1"—a belief that has been consistently passed down since the company’s inception.

Our founder’s motto, “Self-reliance, Professionalism, No.1” embodies the desire for every employee to constantly strive for excellence, never settling for the present.

This philosophy is visually expressed in DAIHO’s emblem, which combines a cursive “D” with the infinity symbol (∞), representing our resolve to break through boundaries and drive transformation.

While we faithfully carry on the founder’s vision and the positive culture cultivated within the DAIHO Group, we also embrace change with a “breakthrough spirit,” adapting boldly to the evolving times, markets, and customer needs.

At DAIHO, every employee shares the goal of ensuring our company remains essential to our customers and the market. To accurately meet customer needs, we have instilled the following four principles as core values throughout our organization.

To meet the needs of today’s market, solid technological capabilities are essential. We aim to build manufacturing environments filled with know-how—factories that earn trust just by being seen.

In today’s rapidly changing global landscape, our customers are under constant pressure to respond swiftly to market demands.

To support their manufacturing needs, we have established production bases around the world and provide a speed-focused support system.

Supporting our customers in the face of intense market competition is also one of our key missions.

Rather than relying on simple price competition, we focus on improving overall production efficiency with a long-term view of the product lifecycle.

Solving our customers’ challenges requires more than just existing technical capabilities.

By fully embracing the creativity that lies at the heart of our management principles, we lead the future of manufacturing with ideas that go beyond expectations.

At DAIHO, we see mold manufacturing—backed by our molding expertise—as a core source of competitive strength that we continue to enhance.

In Japan, we began in-house mold production at our former Yodogawa Plant in 1979. In 1988, we strengthened this capability further through a capital partnership with the former Dainichi Mold Works, aiming to improve both quality and productivity through mold craftsmanship.

In 2012, we expanded this commitment globally by establishing a mold factory alongside our molding plant at DAIHO Indonesia, enabling operations built around internally sourced molds and reinforcing our focus on precision and performance.

We leverage insights gained from past issues to build a knowledge base that informs the design of DAIHO’s original standard molds.

Through defect-type stratification using FMEA, we implement structural designs that address each failure mode, preventing molding defects and significantly improving productivity.

While molds represent a significant upfront investment, there is often pressure to minimize costs. However, by adopting high-efficiency molds with appropriate specifications and pricing, we can reduce the number of cavities required and lower maintenance and repair costs—ultimately helping to control total costs across the entire product lifecycle.

The durability required of a mold varies depending on factors such as lot size and the product's lifecycle before model changes.

Rather than simply pursuing the highest possible quality, we customize our molds by selecting the most suitable steel specifications based on each product’s specific requirements.

To become a manufacturing company truly needed by the market and our customers, our Manufacturing Headquarters focuses on “factory innovation and technological advancement.”

By supporting each site from the head office, we optimize operations across the entire DAIHO Group. This centralized approach brings together DAIHO’s manufacturing strengths and enables us to establish an advanced production management system that directly responds to market needs.

Through initiatives such as mold standardization, flow analysis, high-cycle molding, and zero-burden operations, this office works closely with DAIHO’s molding sites to support productivity improvements and serve as a core driver of technical competitiveness.

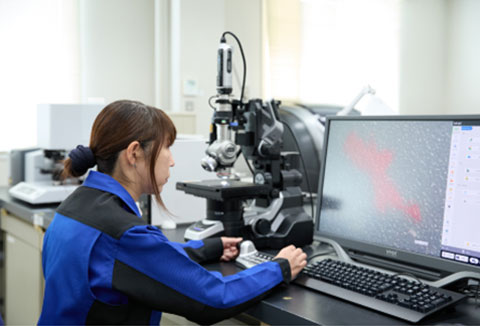

Leading efforts in factory innovation, standardization of production and management, and material analysis support, this office fosters expert molding teams and builds “showcase factories” that embody DAIHO’s manufacturing excellence.

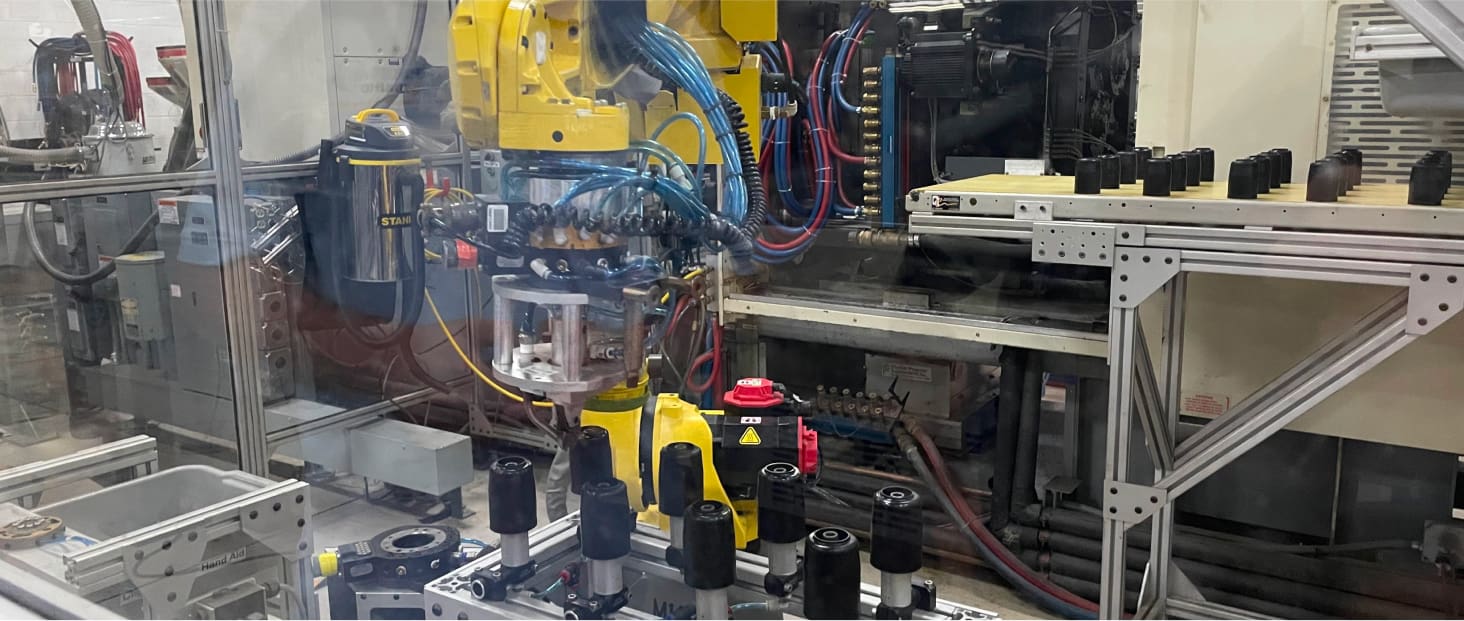

By implementing labor-saving technologies, robotics, and IoT-based condition monitoring, this office develops waste-free production systems while preparing for future labor shortages.

Focused on cutting-edge technological development with a forward-looking mindset, this office responds to emerging societal needs and explores collaborations with academia, government, and industry to further differentiate DAIHO in the marketplace.