Business introduction

For over 80 years since our founding, we have been dedicated solely to manufacturing.

Transforming a customer’s paper drawing into a tangible product is a process filled with challenges.

To meet those demands, we respond with the latest equipment and technologies.

This unwavering approach is the driving force that has been passed down through generations at DAIHO INDUSTRIAL.

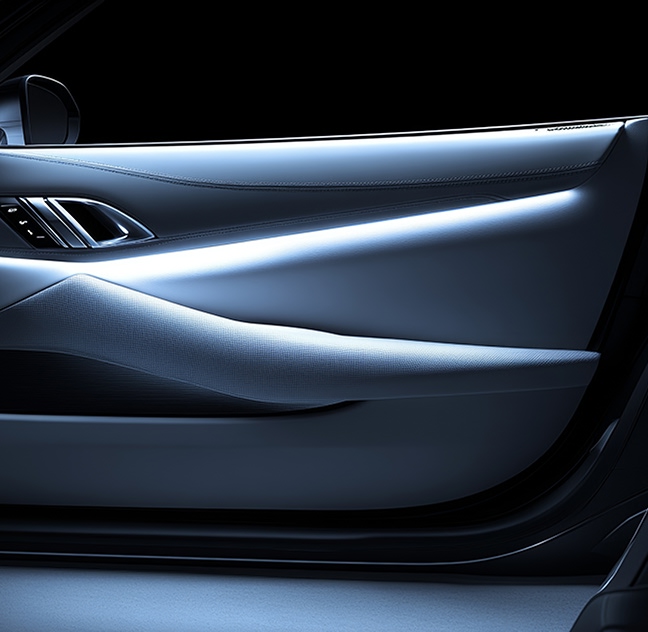

As eco-friendly vehicles, including electric cars, continue to draw attention, our technologies—focused on achieving both lightweight and high strength—are trusted by leading Japanese manufacturers. We produce a wide range of vehicle components such as bumpers, grilles, and both interior and exterior parts.

We manufacture a wide range of components for products used in office environments. Modern office automation (OA) equipment demands both high functionality and refined design. These products require advanced decorative finishes and performance features, and we continue to pursue research and development to meet these evolving needs.

From water-related areas such as kitchens, bathrooms, and toilets to home appliances like refrigerators, cooking equipment, and air conditioning systems—our products play a key role in enriching everyday life at home.

Our products are widely used in medical equipment. Since many of these components require high-volume production under strict quality control, we continuously evolve our processes to meet these demanding standards.

In recent years, plastics have increasingly been seen as harmful to the global environment. At DAIHO, we not only work with petroleum-based plastics but also actively develop products using environmentally friendly materials.

We also operate a proprietary recycling system, enabling us to transform discarded plastic products into new materials. This recycling effort has been ongoing for many years as part of our commitment to sustainability.

We recover discarded products, such as refrigerators, and extract only the plastic materials. These are then washed, deodorized, and treated to regenerate them into materials that perform on par with virgin plastic.