- TOP

- Business

- Craftsmanship

- Sustainability

- Company

- Employee Introduction

-

About This Website

MENU

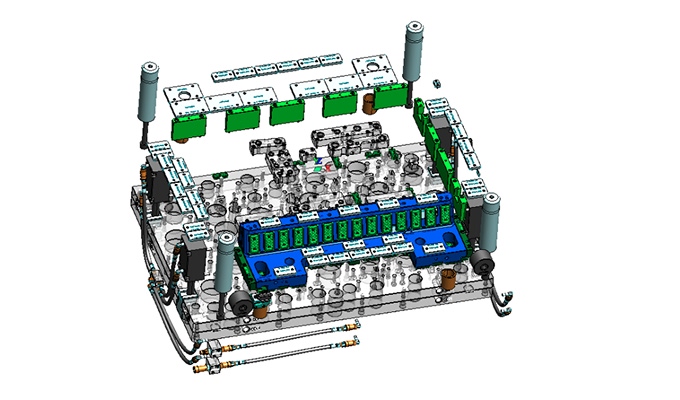

With years of experience in mold manufacturing and unique expertise as a molding manufacturer, the DAIHO Group offers comprehensive support from planning and design to mold production and mass manufacturing. We deliver optimal solutions to a wide range of industries, including automotive parts, housing equipment, medical devices, and consumer goods.

Our product range is diverse, covering automotive parts, AV equipment, consumer electronics, office automation devices, housing equipment, stationery, telecommunications devices, medical instruments, amusement machines, and general merchandise. With in-house mold design teams based in Japan and across Asia, our mold-making is highly regarded for incorporating the unique insights and expertise of a molding manufacturer.

Our primary mold production facility is located in Shiga Prefecture, and we collaborate with partner manufacturers in Japan, Korea, and China to flexibly accommodate rapid production launches. We also maintain and manage molds in-house to ensure consistent delivery of high-quality molds, continually meeting our customers’ expectations.

Here is an overview of the process from the moment we receive your inquiry to the completion of the mold and the start of mass production.

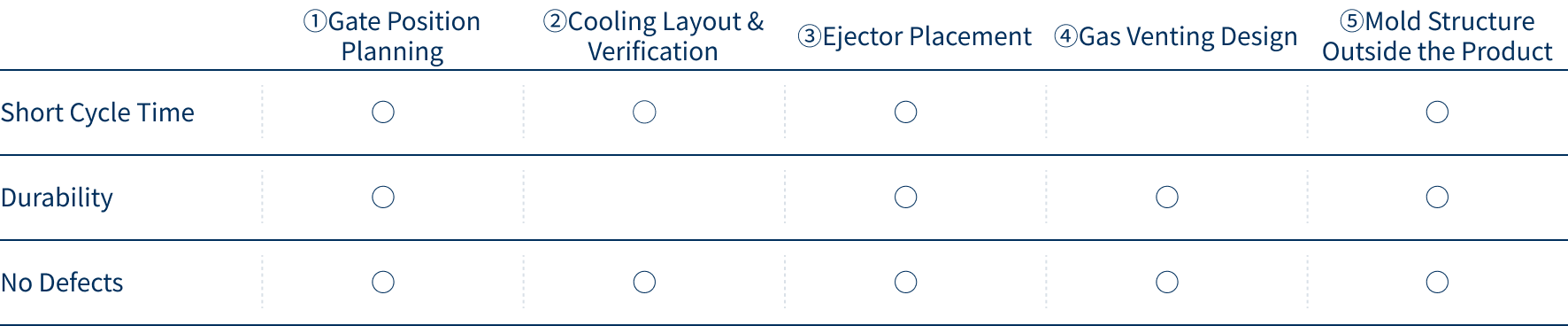

At DAIHO Group, a quality mold is defined as one that offers “short cycle times,” “durability,” and “zero defects.”

PDR(Parts Design Review)

Based on the customer’s 3D data, we verify whether the product can be successfully molded.

Specifically, we examine the following:

①Parting Line Design – Can the mold be properly split?

②Undercut Handling – Can interference during ejection be avoided?

③Draft Angles – Can the product be released smoothly from the mold?

We assess the overall feasibility of molding and propose any necessary modifications or improvements to the customer.

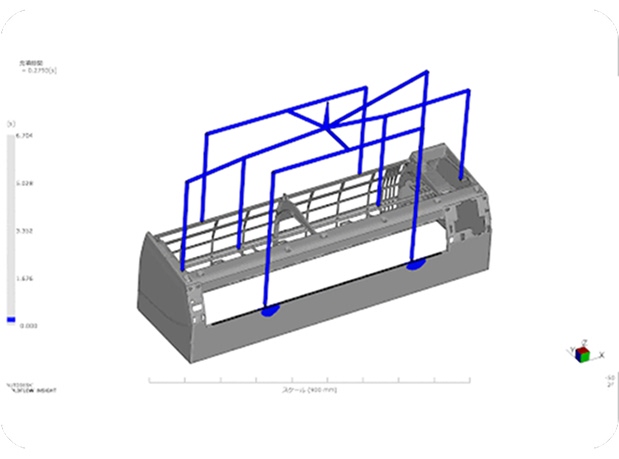

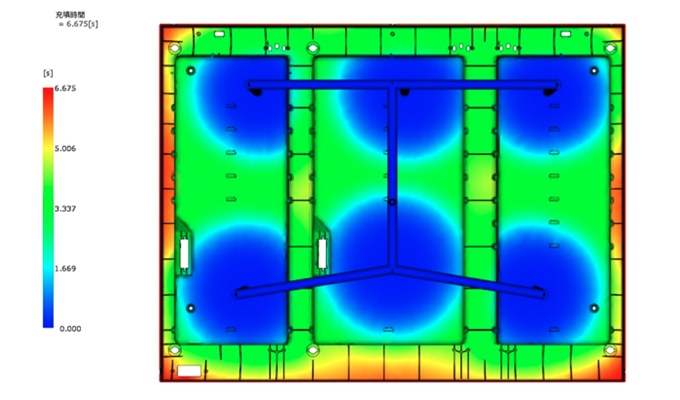

The position of the gate—the resin inlet—has a significant impact on the product’s appearance and quality. In particular, we adjust the weld lines, where resin flows meet, to ensure the desired surface finish.

By ensuring even resin flow and optimizing internal pressure, we minimize the occurrence of burrs (excess flash) and improve mold durability.

In addition, by repeatedly simulating the filling pattern, we propose the optimal molding machine size. This allows for equipment downsizing and maximizes investment efficiency.

MDR1(Evaluation)

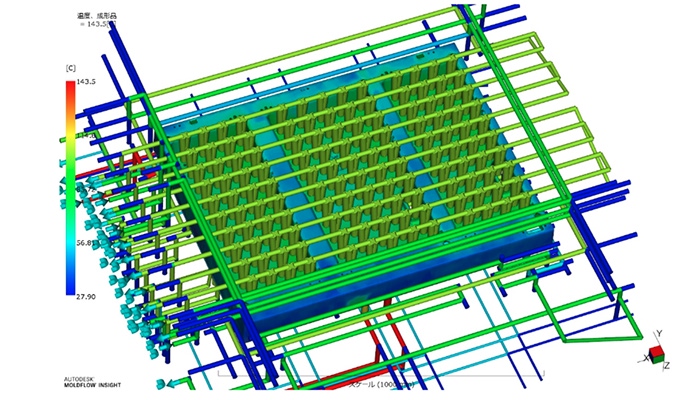

Due to the nature of synthetic resins, shrinkage occurs after molding, significantly affecting dimensional accuracy and warping.

Therefore, it is essential to minimize temperature variations inside the mold and ensure uniform cooling of the resin.

By implementing an optimal cooling layout, we stabilize product quality and prevent deformation or warping. In addition, efficient cooling enables high-cycle molding by minimizing the molding cycle time, contributing to maximum productivity.

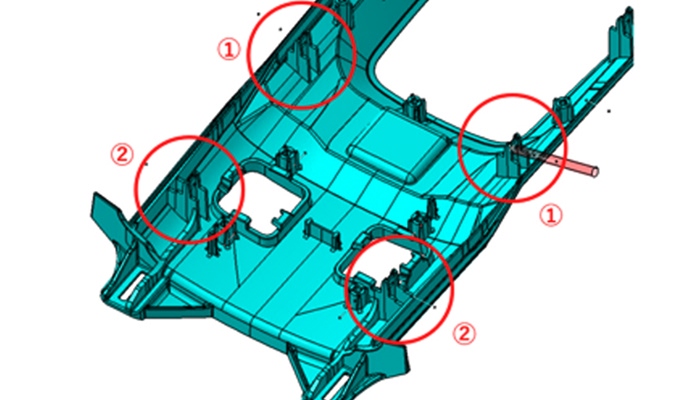

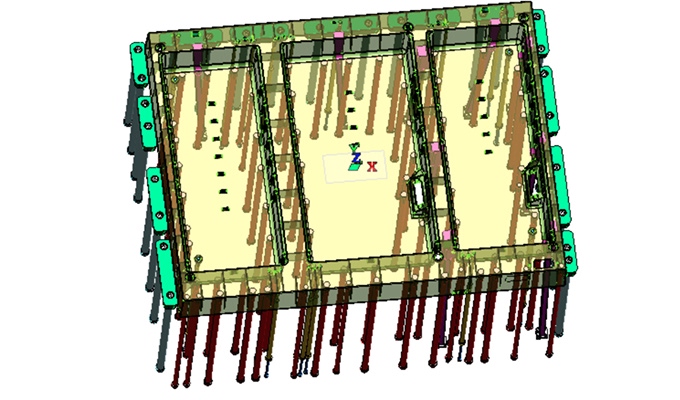

Considering the properties of synthetic resins, it is essential to design an ejector pin layout that ensures smooth product release without deformation, taking product rigidity into account.

To achieve uniform ejection, we place as many ejector pins as possible in appropriate positions to distribute the load evenly. This prevents damage or deformation by avoiding unnecessary stress on the product.

Furthermore, by optimizing the balance of the ejection mechanism, we ensure stable de-molding, contributing to improved molding quality and higher-cycle production.

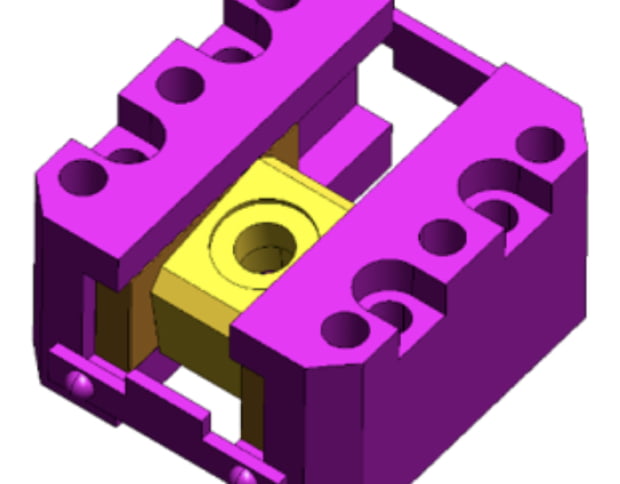

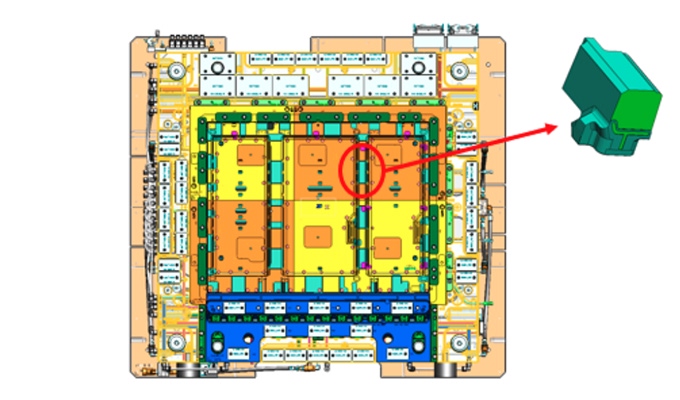

Proper venting of gas generated during resin molding is essential to prevent defects and improve mold durability. Without adequate gas release, issues such as voids or burn marks can occur, leading to reduced product quality and mold corrosion. Therefore, a well-designed venting system is critical.

In addition, dividing high-stress areas into insert structures enhances mold durability and reduces the risk of breakage. Even in the event of damage, partial replacement is possible, allowing for quick repairs and minimizing production downtime.

Ensuring mold durability requires attention not only to the product area but also to the overall mold structure.

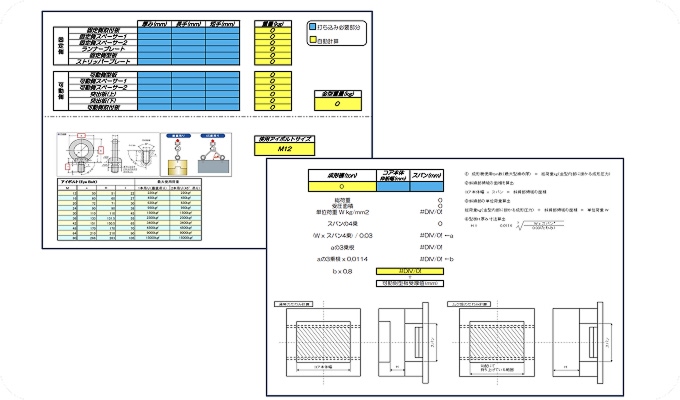

To maintain a compact design while securing durability, appropriate mold support structures and strength calculations are essential.

This is especially critical in high-cycle molding, where faster mold opening and closing demand sufficient pressure-bearing surface areas and proper guide designs for moving components, enabling stable and reliable production.

MDR2(Approval)

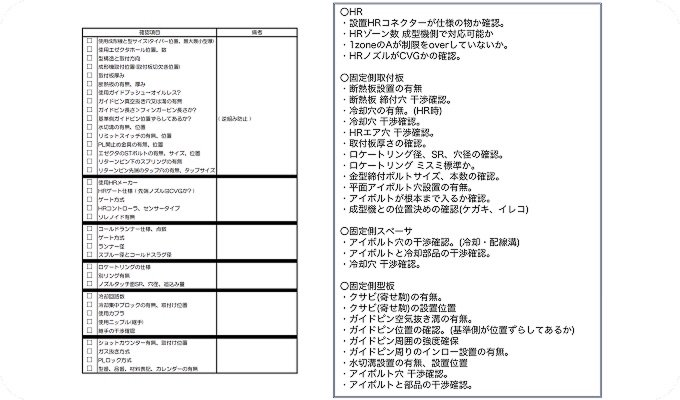

We review the concept drawings submitted by the mold manufacturer based on the following key points:

①Ensuring basic mold strength

②Optimizing the pressure-receiving surface area for the molding machine

③Calculating mechanical components such as spring force

④Verifying compatibility with the molding machine

We verify whether the submitted concept drawing meets the requirements outlined in the mold specification sheet and key design considerations. We also check that the analysis results provided have been properly reflected in the design to ensure its validity.

Only designs that meet these criteria are approved as a “DAIHO-standard mold.”

Validation Testing (Mold Tuning)

The completed mold undergoes performance testing through trial molding using actual production equipment.

By conducting trials early with the actual machines, we support rapid production ramp-up and ensure a smooth transition to mass production.

We also perform a final disassembly inspection to confirm that the mold has been built according to the design and that any issues identified during the trial have been resolved.

Molds that pass this final inspection are declared ready for mass production.