- TOP

- Business

- Craftsmanship

- Sustainability

- Company

- Employee Introduction

-

About This Website

MENU

As we strive to protect the global environment and realize a sustainable society, values such as ethical practices and traceability are gaining importance across generations. The sustainable management and efficient use of natural resources, the significant reduction of waste, and the urgent need to address climate change caused by CO₂ emissions are all pressing global challenges.

However, when it comes to plastic waste, progress on the 4Rs—Refuse, Reduce, Reuse, and Recycle—remains limited. In addition, marine debris such as microplastics continues to pose a growing threat to ecosystems and human health, accelerating the environmental crisis.

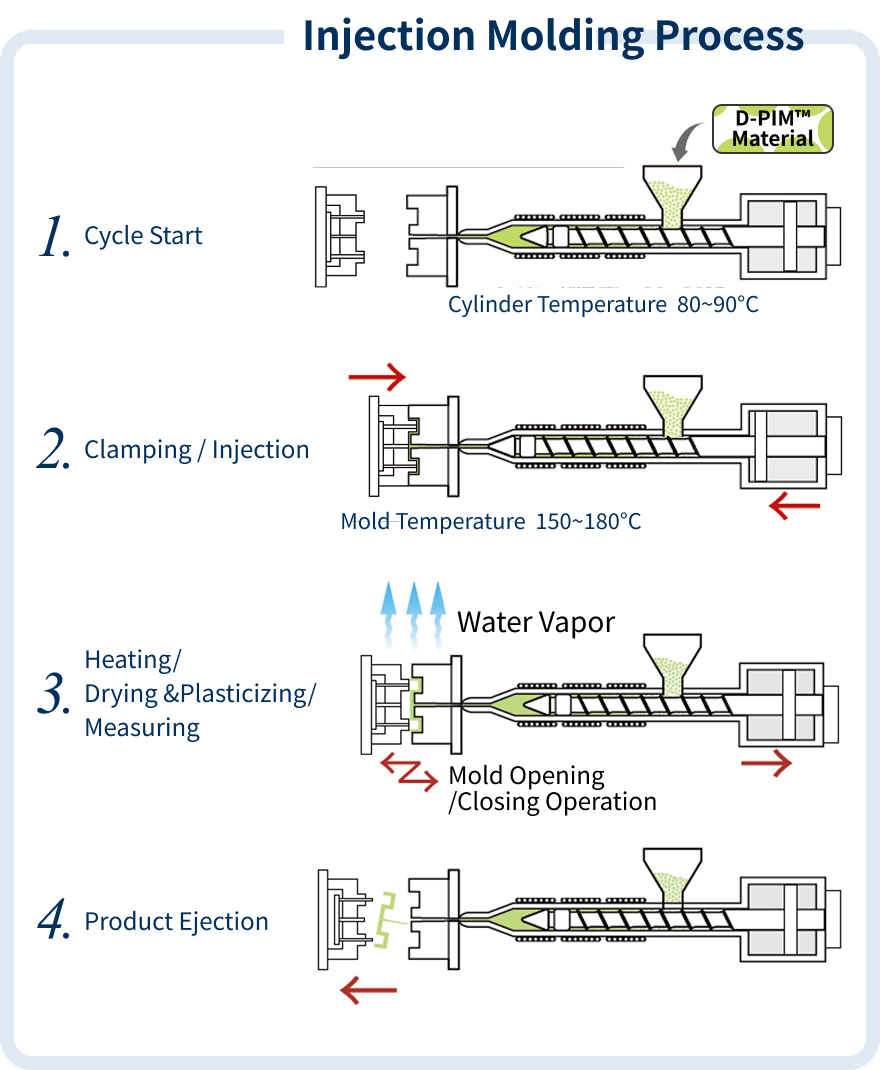

DAIHO’s answer to this challenge is Pulp Injection Molding (D-PIM™)—a new sustainable technology that harnesses the power of nature.

CO₂, a major contributor to climate change, is not only emitted during the production of a product. Emissions occur throughout the entire lifecycle—from fossil fuel extraction and transportation (procurement), to refining and plastic production, distribution and use, and ultimately disposal or recycling. Each of these stages contributes to the environmental burden.

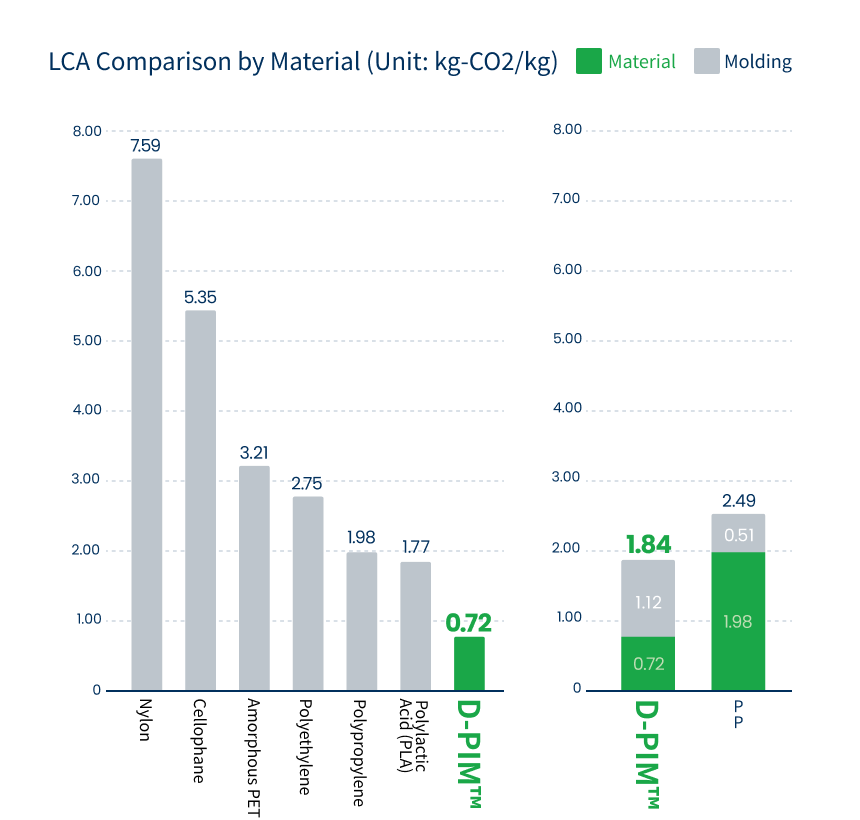

To measure this impact quantitatively, we use a method called LCA (Life Cycle Assessment).

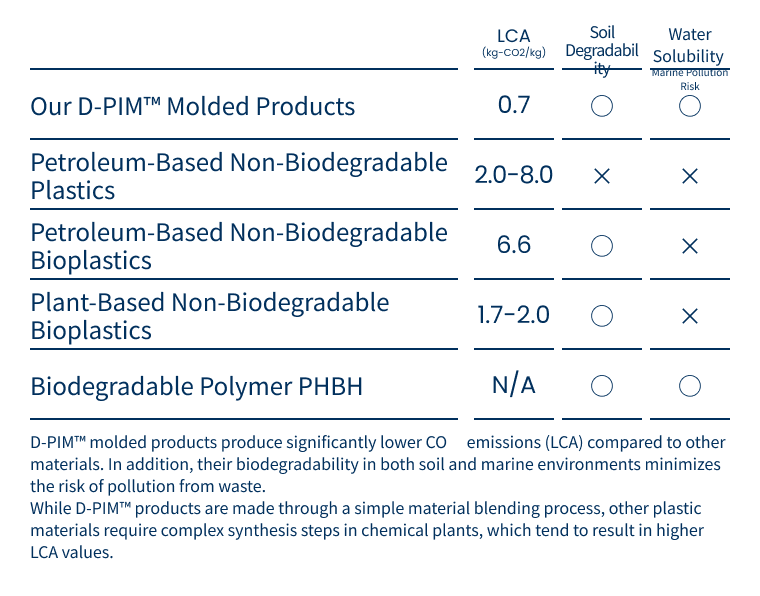

As shown in the graph, D-PIM™ emits significantly less CO₂ not only compared to petroleum-based materials but even to plant-derived bioplastics.

This clearly demonstrates that D-PIM™ is not only a material made from natural sources—pulp and starch—but also a truly sustainable technology that minimizes environmental impact at every stage of its lifecycle.

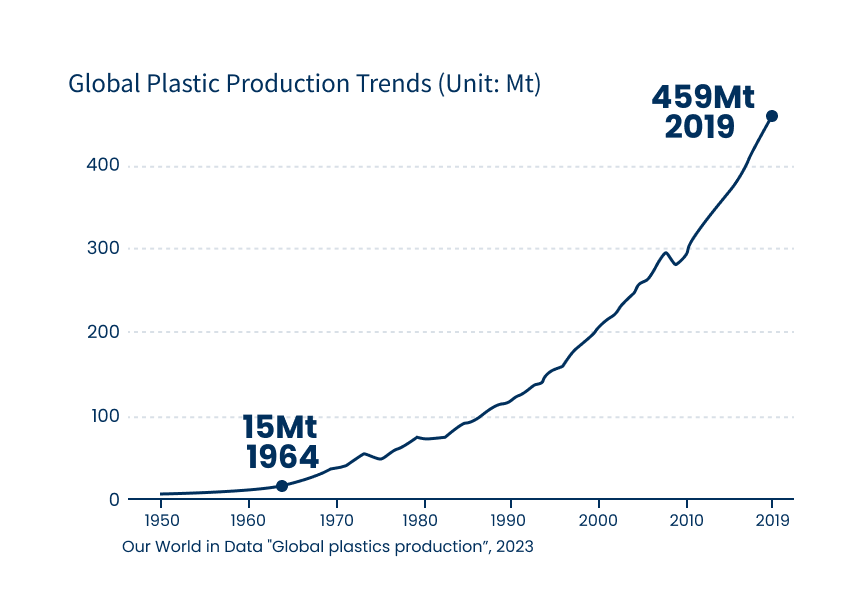

Plastics are convenient and affordable materials that have become indispensable to modern consumer life. However, their significant impact on climate change has become a major global issue.

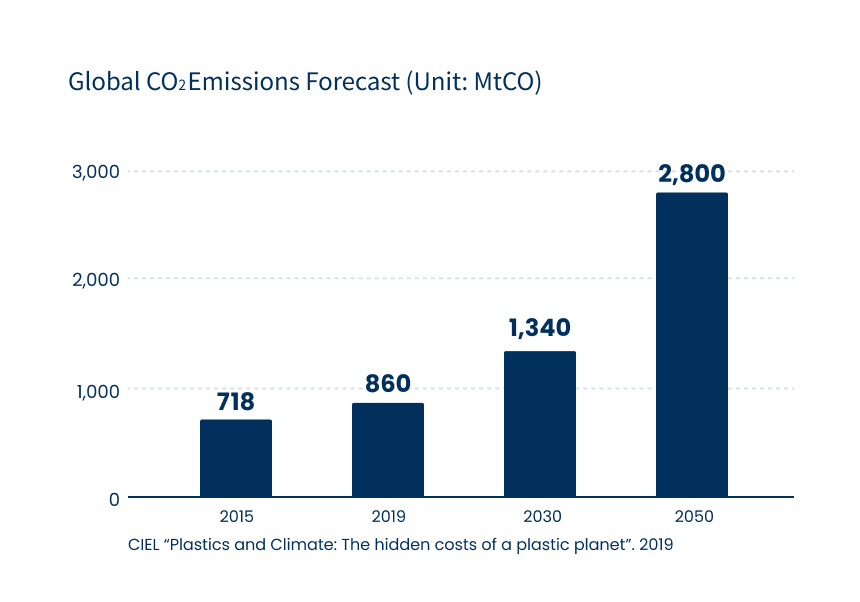

Despite growing awareness, plastic production continues to rise rapidly, with CO₂ emissions from plastics projected to increase dramatically—from 718 Mt in 2015 to 1,340 Mt by 2030, and 2,800 Mt by 2050—an almost fourfold increase.

But the problem doesn’t end there. Discarded plastics—especially lightweight, portable items like PET bottles—are polluting our oceans, which are the source of life on Earth. Alarmingly, at the current pace, it's estimated that by 2050, the volume of plastic waste in the ocean could exceed that of fish.

Marine life is visibly suffering from the effects of plastic pollution, with countless animals injured or killed by discarded materials. Furthermore, the growing concern over microplastics and microbeads—broken-down particles of plastic—is their impact on marine ecosystems and even human health. These particles not only contain toxic additives but also absorb harmful chemicals while floating in the ocean.

The very features that make plastic so useful—durability and water resistance—also mean that it doesn’t break down easily, accumulating in the environment for decades and causing extensive harm.

Even plant-based bioplastics cannot fully resolve this issue.

D-PIM™ is a sustainability technology developed by DAIHO that utilizes the power of nature by injection molding products made from 100% natural materials—combining pulp with plant-based binders.

The resulting products offer outstanding biodegradability, excellent water solubility, zero harmful emissions when incinerated, and top-level recyclability (via both paper recycling and reuse of molding materials). This makes D-PIM™ an ideal solution for reducing environmental impact and eliminating marine pollution.

In addition, D-PIM™ boasts excellent thermal properties for injection-molded products, withstanding high temperatures up to 120°C and low temperatures down to -20°C without any change in physical characteristics.

We live surrounded by the many blessings of forests—paper, wood, plants, and abundant water resources. Forests also play vital roles in providing habitats for wildlife, absorbing carbon dioxide, producing oxygen, and preventing landslides.

Unfortunately, deforestation and the destruction of nature continue in the name of economic and industrial development.

At DAIHO, we believe this must never happen. We deeply resonate with the values of FSC, which promotes the responsible management and preservation of forests. That’s why we are highly selective about the pulp used in our products—our PIM technology uses only FSC-certified pulp.

Inspired by the 1992 Earth Summit held in Rio de Janeiro, interest in “environmental conservation and sustainable development” grew rapidly across Japan, sparking an eco-conscious movement. At DAIHO INDUSTRIAL, we began exploring the idea of creating molding materials from paper waste. Responding to customer inquiries, we started prototyping PIM (Pulp Injection Molding) and steadily built a track record of commercialized products.

・Obtained the first patent for pulp injection molding technology

・Acquired the trademark for PIM

・Improved the existing method and began mass production

・Established a dedicated production facility at the Tottori Plant

・Began production of ampoule cases for a major pharmaceutical company

・Started production of first-generation file binders (KOKUYO MVP Co., Ltd.)

By the mid-2000s, eco-friendly products like recycled goods and energy-efficient appliances had become somewhat mainstream. However, with many of these products priced at a premium, the environmental boom began to settle. As cost-performance became a critical factor, PIM also faced pressure to improve productivity. We deepened collaboration with external research institutions and optimized our injection molding machines and production systems, achieving a significant reduction in cycle time.

・Launched joint research to improve productivity with the Yokoi Laboratory at the University of Tokyo and NISSEI Plastic Industrial Co., Ltd.

・Began production of CD cases for a major music content company

・Established the PIM Consortium under the Foundation for the Promotion of Industrial Technology

・Improved productivity by 60% through optimization of molding machine operation and mold conditions

・Launched the second PIM consortium focused on runnerless molding

・Began production of media tape cases for a major PC manufacturer

・Started production of "Piri-Piri" sticks for an agricultural material manufacturer

・Began production of second-generation file binders (KOKUYO MVP Co., Ltd.)

Acquired Tottori Green Product Certification

・Developed material marking method through flow property analysis of PIM materials

・Relocated the production facility to the Ashikaga Plant

・Jointly developed paper insert molding technology with Nissha Co., Ltd. (formerly Nissha Printing Co., Ltd.)

・Updated to the current production system

・Started pilot production of Takasaki Daruma

Developed viscosity measuring equipment for PIM materials

As demand increased across a wide range of applications, we expanded our lineup of materials and grades and prepared for mass production. A key turning point came when our PIM capsules were adopted by a major conveyor belt sushi chain. Since then, orders for D-PIM™ have continued to grow rapidly, and both production volume and demand remain on an upward trajectory.

・Consolidated mass production and R&D at the Tottori facility

・Jointly developed riverbank plant growth control containers with Professor Oka’s Laboratory at Tottori University’s Faculty of Agriculture

・Began production of cosmetic cases for a major cosmetics company

・Signed a non-exclusive license agreement with a major printing and molding manufacturer

・Started production of toy capsules for a major conveyor belt sushi chain

・Launched sales of PIM materials

・Began production of amino acid sticks for plant activation for an agricultural material manufacturer

・Established the PIM Material Development Lab in Mishima City, Shizuoka Prefecture

・Signed a non-exclusive license agreement with an automotive plastic parts manufacturer

・Renamed PIM to D-PIM™, incorporating DAIHO’s “D” into the brand