- TOP

- Business

- Craftsmanship

- Sustainability

- Company

- Employee Introduction

-

About This Website

MENU

We are dedicated to advancing nature-based sustainable technologies and promoting the reuse and recycling of waste materials.

We are developing environmentally conscious new materials and our proprietary recycling systems to reduce environmental impact through innovative technologies.

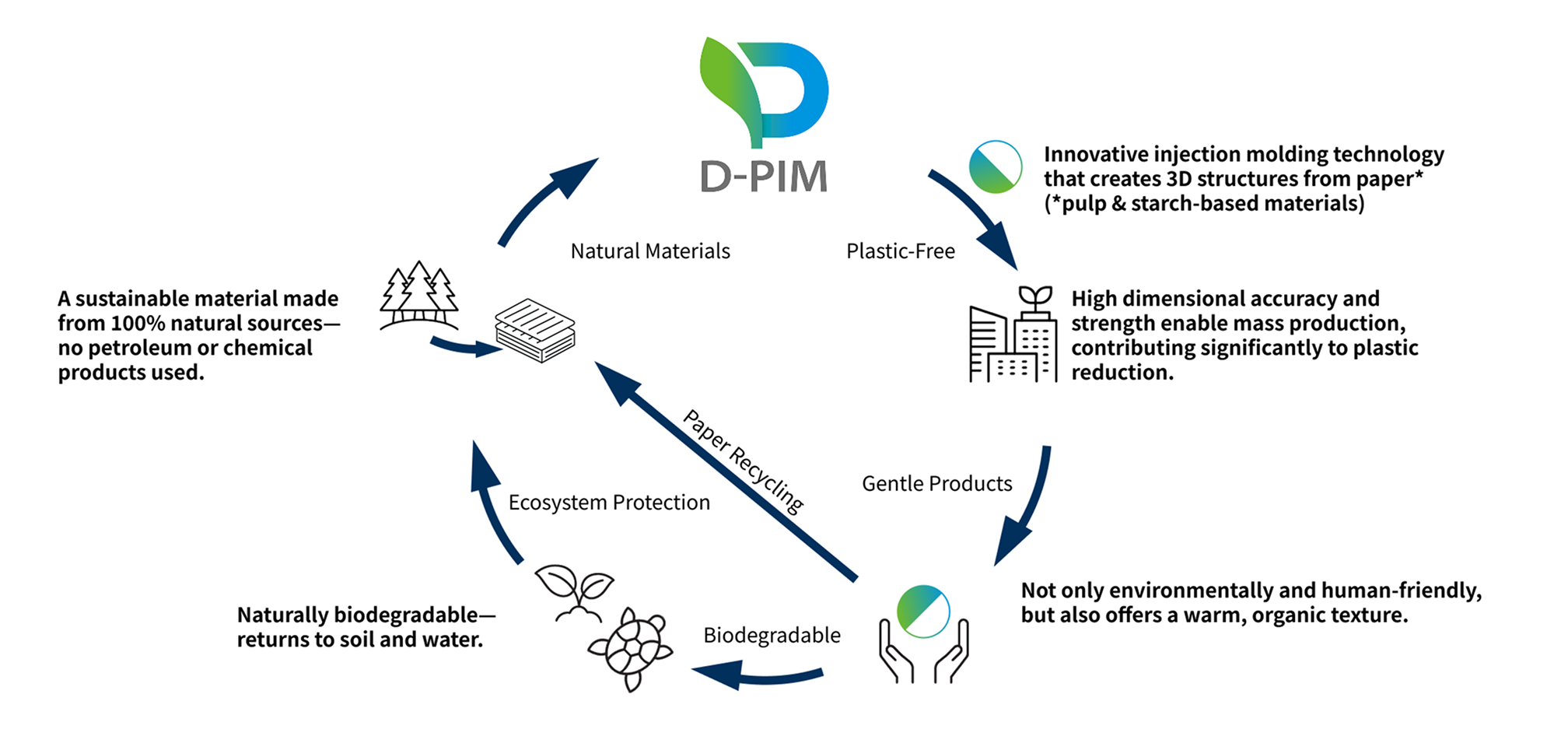

D-PIM™, which uses pulp and starch as raw materials for injection molding, is not only a plastic alternative but also a sustainable technology that significantly reduces environmental impact—including CO₂ emissions—throughout its lifecycle.

We recover polypropylene (PP) resin from discarded home appliances and produce recycled resin that meets the standards of Japan’s Food Sanitation Law.

To contribute to global environmental conservation, we are advancing product development that leverages D-PIM™ technology and our proprietary recycling systems.

As society faces growing concerns over plastic recycling and marine pollution caused by microplastics, we have leveraged our long-standing expertise in plastic processing to develop D-PIM™ (Pulp Injection Molding)—a technology that uses paper-based materials to produce products with physical properties comparable to plastic.

More than just a plastic alternative, D-PIM™ is a truly sustainable technology, offering low CO₂ emissions, excellent biodegradability, and reduced environmental impact across a wide range of applications.

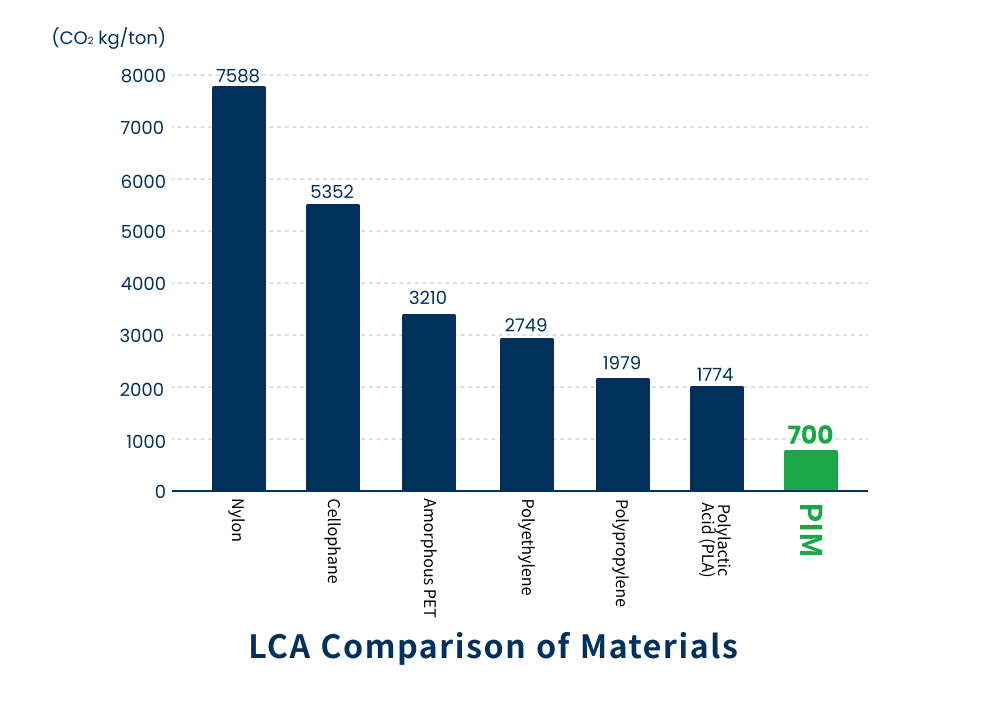

D-PIM™ significantly outperforms not only petroleum-based materials but also plant-derived bioplastics in terms of CO₂ emissions. Made from natural materials such as pulp and starch, D-PIM™ contributes to the prevention of global warming and CO₂ reduction by promoting its widespread adoption.

D-PIM™ is recognized not only as a plastic alternative with high biodegradability and low CO₂ emissions, but also as a material with minimal environmental impact across a wide range of applications.

To maximize these advantages, we continue to refine our product design and manufacturing processes.

DAIHO INDUSTRIAL’s Eco Recycling System recovers polypropylene (PP) from discarded home appliances. After undergoing metal and contaminant removal processes, the material is treated using our proprietary washing system and natural cleaning agents. This enables the recycled resin to be safely reused in products that come into contact with food, meeting strict hygiene standards.

Plastic materials brought in from home appliance recycling facilities are processed using specialized equipment to remove metals and foreign substances, extracting only recyclable resin.

The extracted plastic is washed using a proprietary system and a 100% natural cleaning solution that complies with food safety regulations, effectively eliminating odors from the waste plastic.

The cleaned material is thoroughly dehydrated and dried to prepare it for reuse.

The result is high-quality recycled polypropylene (PP) that is safe for use in products that come into direct contact with food.

Using 100% recycled material, we manufacture components for home appliances through plastic molding.

We aim to expand awareness of D-PIM™, a groundbreaking sustainable technology, and work together with our customers to create environmentally responsible products that also deliver new value.

For our recycling system, we are strengthening quality assurance of recycled resins by enhancing resin property testing equipment and improving our operational framework. This enables us to develop original recycled resins that meet the specific performance requirements of our customers.

As environmental issues continue to gain global attention, our D-PIM™ technology and eco recycling systems are expected to play a vital role in contributing to a more sustainable future society.