- TOP

- Business

- Craftsmanship

- Sustainability

- Company

- Employee Introduction

-

About This Website

MENU

We lead initiatives in factory innovation, production and management standardization, and material analysis support, while cultivating expert molding teams. Our goal is to improve quality through the creation of “showcase factories,” and we provide support across all production sites to achieve this vision.

By leveraging digital transformation (DX) to rapidly identify issues, plan countermeasures, execute, and verify results, we accelerate the PDCA cycle. This process not only enables quick action but also leads to the accumulation of valuable data and know-how for our in-house mold development.

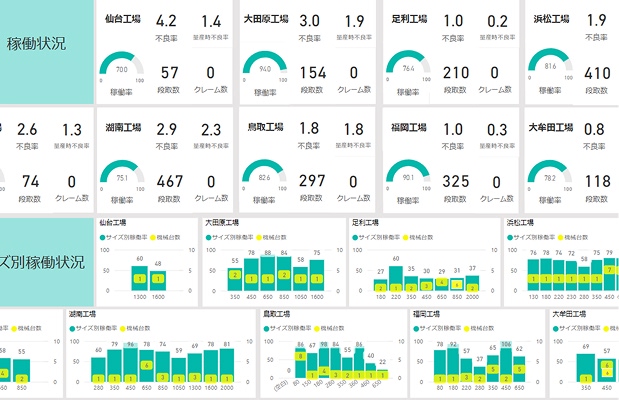

We are unifying operational analysis data across all factories and visualizing production losses. By utilizing the latest BI technologies, we promote real-time nationwide data sharing to drive transparency and informed decision-making.

We focus on ensuring that “the right items” are “in the right place” and “arranged in the right way,” so they are “immediately accessible when needed” and “visually tidy”—a foundation for operational efficiency.

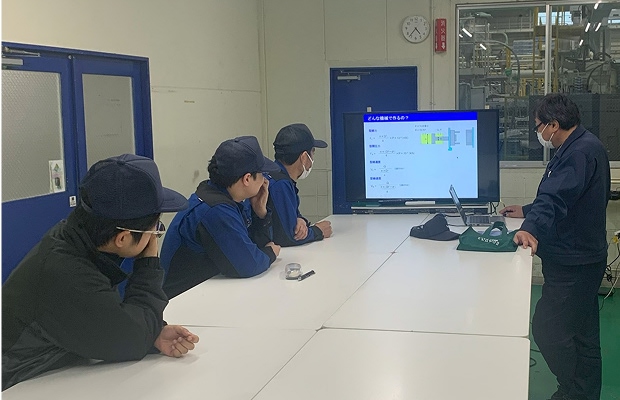

We are committed to securing top-tier engineers at every factory. By supporting the development of molding technicians, we actively address the challenge of passing on technical expertise to the next generation.

By visualizing various types of data in real time, we enable immediate decision-making and maximize operational efficiency across our production sites.

In addition to providing technical support for the introduction of painting technologies, production equipment, and jigs and tools, our office also plays a key role in transferring efficiency-enhancing technologies developed in Japan to our overseas sites.

At the company-wide level, we are also committed to developing global talent. As part of this initiative, we offer overseas training programs for new graduates starting from their first year of employment.

As a molding manufacturer, we provide training and support for employees who wish to develop their molding skills. This initiative is open to all, regardless of department or gender, ensuring broad access to technical education.

Using state-of-the-art equipment, we conduct fast and accurate analyses—such as foreign material composition testing—to identify root causes. Results are compiled into reports and distributed to each factory for review and action.

We create instructional videos, propose training methods, and systematically organize defect prevention techniques to enhance operator education and skill building.