- TOP

- Business

- Craftsmanship

- Sustainability

- Company

- Employee Introduction

-

About This Website

MENU

On April 1, 1998, the extrusion division of DAIHO INDUSTRIAL, which had been manufacturing and selling air conditioning components under the “TYLON™” brand, was spun off and relaunched as an independent manufacturing and sales company.

With a clear commitment to independent and accountable management, and through the dedicated efforts of our employees and the strength of our manufacturing capabilities—along with the strong support of the DAIHO Group—we have steadily continued to grow and expand our business.

At TYLON™, we go beyond simply manufacturing and selling catalog products—we specialize in solution-based sales, deeply understanding our customers’ challenges and needs to propose the most suitable solutions.

For example, when visiting a customer’s facility to discuss their requirements, if our existing products don’t fully meet the specifications, we can create a prototype on the spot using our core offerings such as flex hoses or glass ducts.

By reviewing the prototype together, we can refine the specifications in real time while discussing price, lead time, and other conditions—ensuring that we provide solutions aligned with key customer priorities, without wasting valuable time.

Even if the request is as broad as “improving HVAC efficiency for a building,” we welcome the challenge. Leveraging our technical expertise and manufacturing capabilities, we help clarify customer issues and provide exceptional value through a cycle of design, prototyping, testing, and refinement.

More than just a supplier of HVAC components, TYLON™ is recognized for solving air system challenges and delivering value through solution-based sales—earning the trust of many customers and establishing ourselves as a long-term business partner.

TYLON™ contributes to improved energy efficiency in HVAC systems through its extensive product lineup and complementary components. In large facilities such as office buildings, commercial centers, factories, hotels, and hospitals, HVAC systems can account for 30–50% of total electricity usage. By enhancing air conditioning efficiency, we help reduce overall power consumption across society and lower CO₂ emissions from fossil fuels.

Moreover, high-efficiency HVAC systems emit less waste heat, which helps mitigate the urban heat island effect—localized temperature increases in city environments. By reducing electricity demand for businesses, these solutions also support the transition toward renewable energy, which remains relatively costly in Japan. In this way, TYLON™ plays a role in advancing the realization of a more sustainable energy society.

TYLON™ actively promotes the use of environmentally conscious materials as part of its efforts to support a circular economy. Recently, in collaboration with partner companies, we have developed products using a highly recyclable non-combustible cardboard material. Made from recycled paper and used cardboard, this material not only helps conserve forest resources but is also significantly lighter than traditional metal or plastic ducts. As a result, it contributes to reduced CO₂ emissions during both manufacturing and transportation.

This product has been selected for use at the 2025 World Expo in Osaka, Kansai, and will serve as a symbol of sustainability under the theme of "Designing Future Society," sharing the importance of environmental responsibility with the global community.

TYLON™s HVAC technology prioritizes not only comfort, but also safety and peace of mind. In factories and warehouses, proper climate control reduces the risk of heatstroke and dehydration, helping to protect the health and safety of workers. A comfortable working environment fosters mental well-being, which in turn helps reduce human error and workplace accidents, while also improving employee retention. We also view improved comfort in educational settings as a vital social issue. Children are more vulnerable to heat-related illnesses than adults, and classroom air conditioning plays a major role in their ability to concentrate. Proper HVAC not only supports health but also enhances learning outcomes. In recent years, public awareness around indoor air quality has grown significantly. At TYLON™, we continue to provide optimal solutions that address the needs for efficient ventilation and cleaner indoor air. Through TYLON™’s HVAC technologies, we are committed to building a better future for society and the environment.

TYLON™ traces its origins to the development of extrusion molding technology through a technical partnership with West Germany’s ATLANT company, and the installation of extrusion molding machines at the Yodogawa Plant. At the time, most production was custom-made, including components such as handles for radios and reinforcements for home appliances.

TYLON™ also began developing flexible hoses, which were not yet distributed domestically. These were mainly used for agricultural irrigation and powder transport, such as wheat flour and rice husks. However, demand was still limited in those early days.

・Yoshitaka Ochi (then Assistant Manager) studies abroad in West Germany for new product development

・Began extrusion molding operations at DAIHO INDUSTRIAL’s Yodogawa Plant

・Began production of radio cassette handles for Matsushita Electric Industrial Co., Ltd. (now Panasonic Corporation)

TYLON’s flexible hoses were adopted for local cooling ducts on factory assembly lines. This led to growing recognition from major domestic HVAC manufacturers, and the hoses began seeing wide use in commercial and retail HVAC systems.

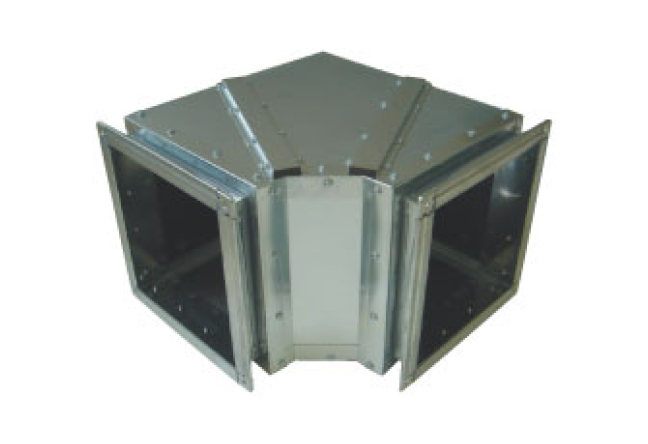

As business expanded, TYRON™ began developing glass ducts and air terminal boxes (chamber boxes), evolving into a comprehensive HVAC component manufacturer throughout the 1980s and 1990s, with products used in everything from building systems to residential air conditioning.

・TYLON flexible hoses adopted for cold air ducts in spot air conditioners

・Developed water-stop boards for highways using PVC-based elastomer extrusion molding

・Developed dual-color (rigid and soft) extrusion profiles

Produced:

・Rigid PVC piping covers for refrigerant pipes (residential use)

・Air conditioner filter frames and louvers with flocked surfaces

・Acrylic trims for commercial refrigerators (for supermarkets and convenience stores)

・ABS reinforcement components for TOTO storage units and A/C grille parts

・Opened Hirakata Plant in Deguchi, Hirakata City as a dedicated extrusion factory (DAIHO INDUSTRIAL Extrusion Division)

・Launched manufacturing and sales of glass ducts

・Began manufacturing and sales of chamber boxes

・Nasu Plant started operations, producing chamber boxes

・Opened second Hirakata Plant as a dedicated glass duct facility

・Established Nagoya Sales Office

・Nasu Plant begins production of flexible hoses and glass ducts

In 1998, the extrusion division of DAIHO INDUSTRIAL was spun off to form an independent entity focused on the manufacturing and sales of HVAC components. The name “TYLON,” previously used as a product brand, was adopted as the company name.

This move reinforced the company’s commitment to autonomous, responsible management and helped strengthen its brand identity. Today, “TYLON™” is widely recognized throughout the HVAC industry.

・Spun off from DAIHO INDUSTRIAL as TYLON Co., Ltd. with Yoshitaka Ochi as first president

・Opened sales office and subcontracting plant for glass ducts in Oita to promote business in Kyushu

・Settsu Plant began operations, focused on R&D for new products

・Tokyo Sales Office opened in Akabane, Kita-ku, Tokyo

・Consolidated all factories and relocated Hirakata Plant to current location in Kasugakita-cho

・Relocated Oita Plant to Fukuoka, started operations of TYRON Fukuoka Plant within DAIHO INDUSTRIAL’s Fukuoka Plant for glass duct production

・Shinzo Saito appointed as third president

・Fukuoka Plant officially began operations

・Opened Sendai Plant and Sales Office for chamber box production

・Omuta Plant and new Fukuoka Sales Office opened for glass duct and chamber box production

・Chubu Plant and Chubu Sales Office opened for production of glass ducts and chamber boxes

TYLON’s fifth production site, the Otawara Factory, officially began operations, joining the ranks of Hirakata, Nasu, Chubu, and Omuta.

With the slogan “Creating the Future of HVAC Components,” the Otawara facility serves not only as a production hub but also as a product showroom where customers can see TYLON™ solutions in action.

As a new center of innovation, the factory will deliver even greater value to customers by supplying the HVAC components they need—efficiently and reliably.

Otawara Plant begins full operations, producing chamber boxes